Quality Control

Top King Steel’s quality control department is the strongest and most independent department in our company. We have a well trained professional quality control team and are committed to providing high quality steel products to our business partners. We assure our business partners of carrying out each order successfully.

Meanwhile, we have very good cooperation with SGS, BV and ITS. All clients can ask for any third party to take quality inspection.

1. Inspecion

Top king believes Quality is the core of success in an ever-changing business environment. Quality Assurance in Top King’s Quality Management System is not merely limited to the physical inspection of cargo, it has also incorporated some conscientiously well-planned and systematic checking activities to meet customers’ expectations for quality products and services.

1.1 Quality Inspection items:

a. Check the compliance of the quality certificate.

b. Painting mark of the steel.

c. Appearance and dimension of the steel.

d. Weight of the steel.

1.2 Surface quality

There should not be crack, folding, scab and impurity on the surface of the steel; and there should not be layer division and cavity contraction trace on the end.

1.3 Steel weight

1.3.1 The actual weight is normally got by weighing method, with allowable difference of 0~+6‰.

1.3.2 In case that weighing is impossible, the weight can be calculated by theoretical calculation

2. Sampling

With Top king’s Sampling System, preparing samples for testing is no longer a tedious job. We are pleased to help organize cargo inspections in a one-stop service, from booking the inspection time, marking the material, cutting the sample, delivering to test center to submitting the test report. Therefore, all you need to do is sit laid-back in comfort and let us do all that for you.

The chemical composition should meet the corresponding state (Or industrial) standard, specified international standard or order contract (Or technical agreement).

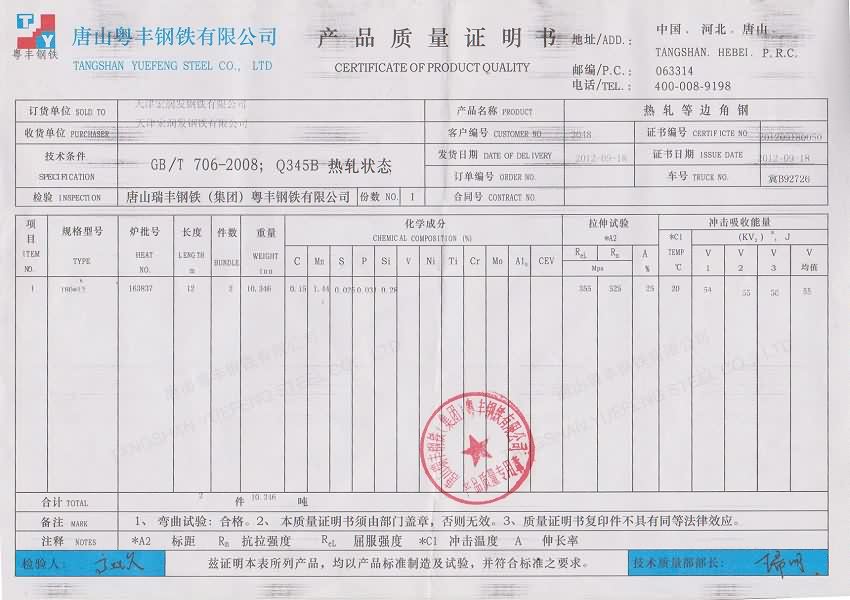

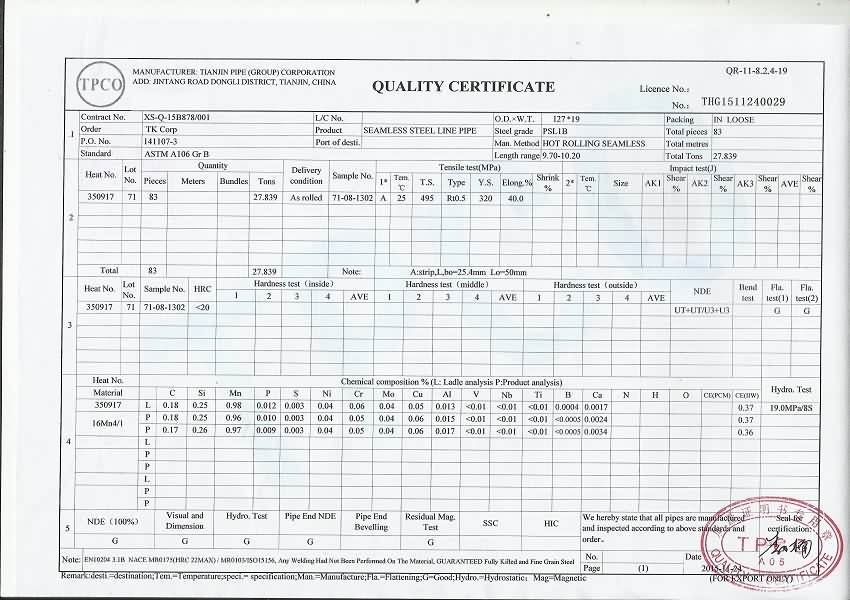

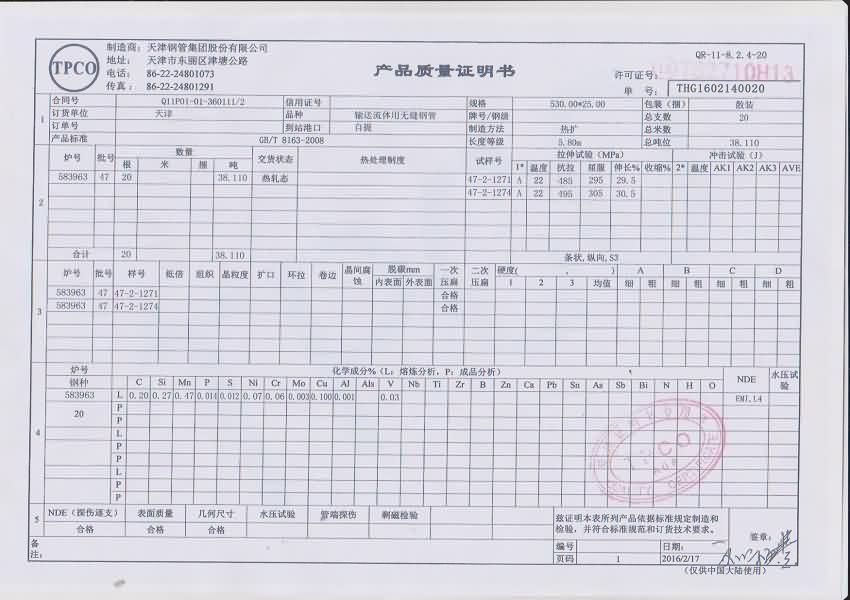

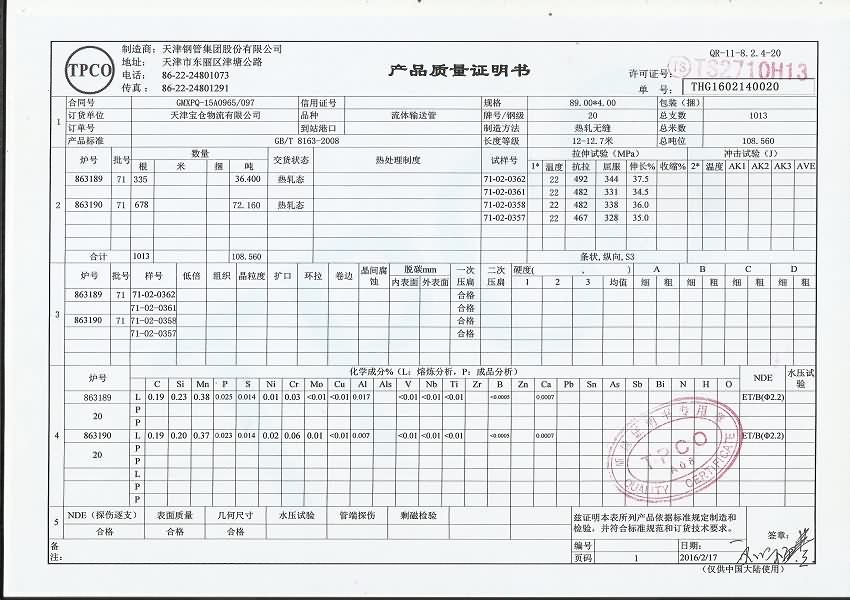

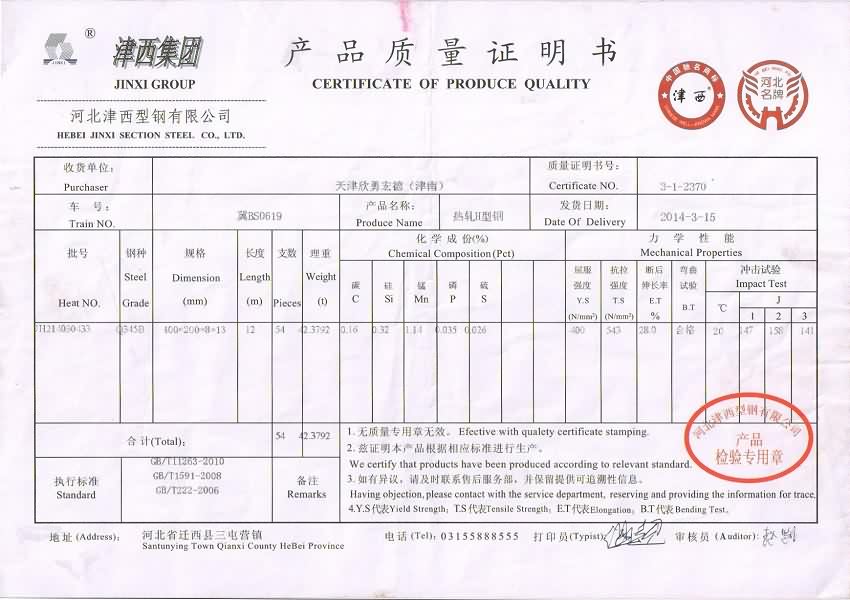

3. Quality Certificate

Top King will require all the holding company or supply factory issue the steel quality certificate (Or certificate of approval) per lot. All the inspection results in the quality certificate should meet the standard. The quality certificate should at least include the following contents:

a. Manufacturing factory, production lot No. (Or furnace No.) and contract No.

b. Material grade and level.

c. Material name, type, size and delivery condition.

d. Delivery quantity and weight.

e. Inspection report of all inspection items.

f. In case that there are special requirements in the drawing or order technical requirements, the quality certificate should also include the inspection report of the special items.

g. The quality certificate should have the dedicated inspection seal of the company workshop or the quality inspection department of the supply factory, seal of the inspector, as well as “Qualified” seal in delivery.

The quality certificate should have complete signatures and be filled according to standard and complete. In case that the bilingual certificate is required, the company standard will prevail.

4. Packing and Marking

Top King offers a wide range of packing solutions and markings:

Anti-corrosion shop primer.

Full set of pretreatment: bed cleaning, derusting, lacquering, Painting.

High quality, durable plastic packing.

Edge protection.

Product identification by marking on the steel product.

Self-adhesive product label.

Customized packing and marking.