We have established a steel deep processing plant to provide the service of steel cutting, drilling, beveling, bending and welding. However you need your steel processed, just supply your drawings in any format, we can do it accurately. Our goal is to reduce your time and cost, ensuring you’re always staying competitive.

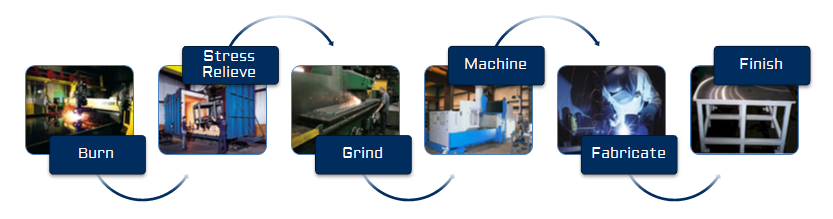

The following are the typical steps, which we use to produce a completely machined and surface ground part:

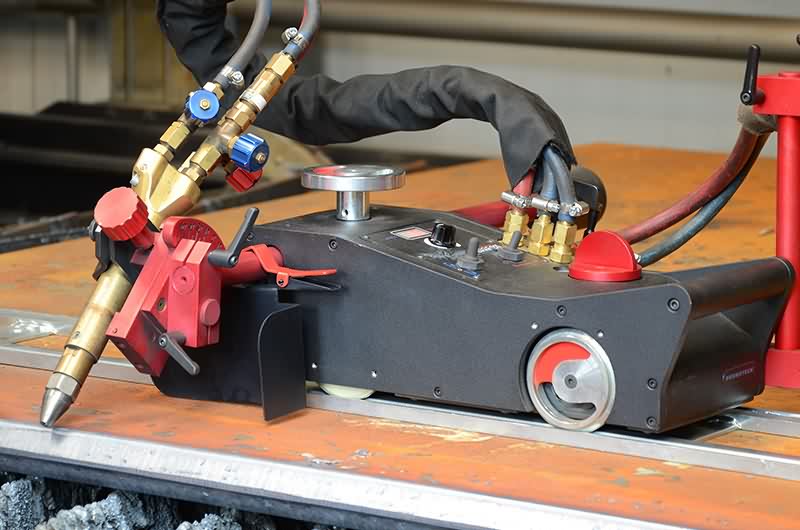

Step 1: Burn or plasma cut plate per CAD requirements

Step 2: Stress relieve or anneal for improved machining and flatness

Step 3: Blanchard grind to finishing thickness

Step 4: Mill edges, holes, slots or other details per drawing specifications

Step 5: Fabricate and assemble multiple components, can include welding or custom machine building

Step 6: Surface Grind piece to the highest flatness and parallelism requirements

Step 7: Sand blasting and painting (if required)

Step 8: Inspect to insure highest quality and accuracy